Prototyping in packaging design is the art (and science) of turning ideas into tangible mock-ups before hitting full production. It’s the creative bridge between scribbled napkin sketches to the retail-ready beauty sitting on the shelf.

Far from being just a checkbox on a to-do list, prototyping plays a key role in iterative brand design and testing. It helps brands in spotting flaws, validating concepts, and refining usability. In short: it saves money, avoids embarrassment, and makes everything look better.

This guide dives into why prototypes matter, what tools packaging designers use, and how an iterative mindset can make all the difference between meh and mega.

Prototypes in packaging design are strategic assets. Their job? To visualise, validate, and evolve ideas before you commit to large-scale printing, material choices, or structural die-lines.

One of the biggest perks? Risk mitigation. A prototype lets you test your concept in the real world – with clients, retailers, and even your friends – to see how it performs. From visual aesthetics to functionality and sustainability messaging, packaging prototypes help identify the weak spots before they become costly.

But here’s where they really shine: real-world testing. Prototypes are perfect for running feedback sessions or focus groups. Instead of guessing how customers might react, you give them something to hold, open, critique, or love.

And when you’re working within a budget (spoiler: everyone is), prototypes help ensure you’re not wasting time or materials in a direction that flops.

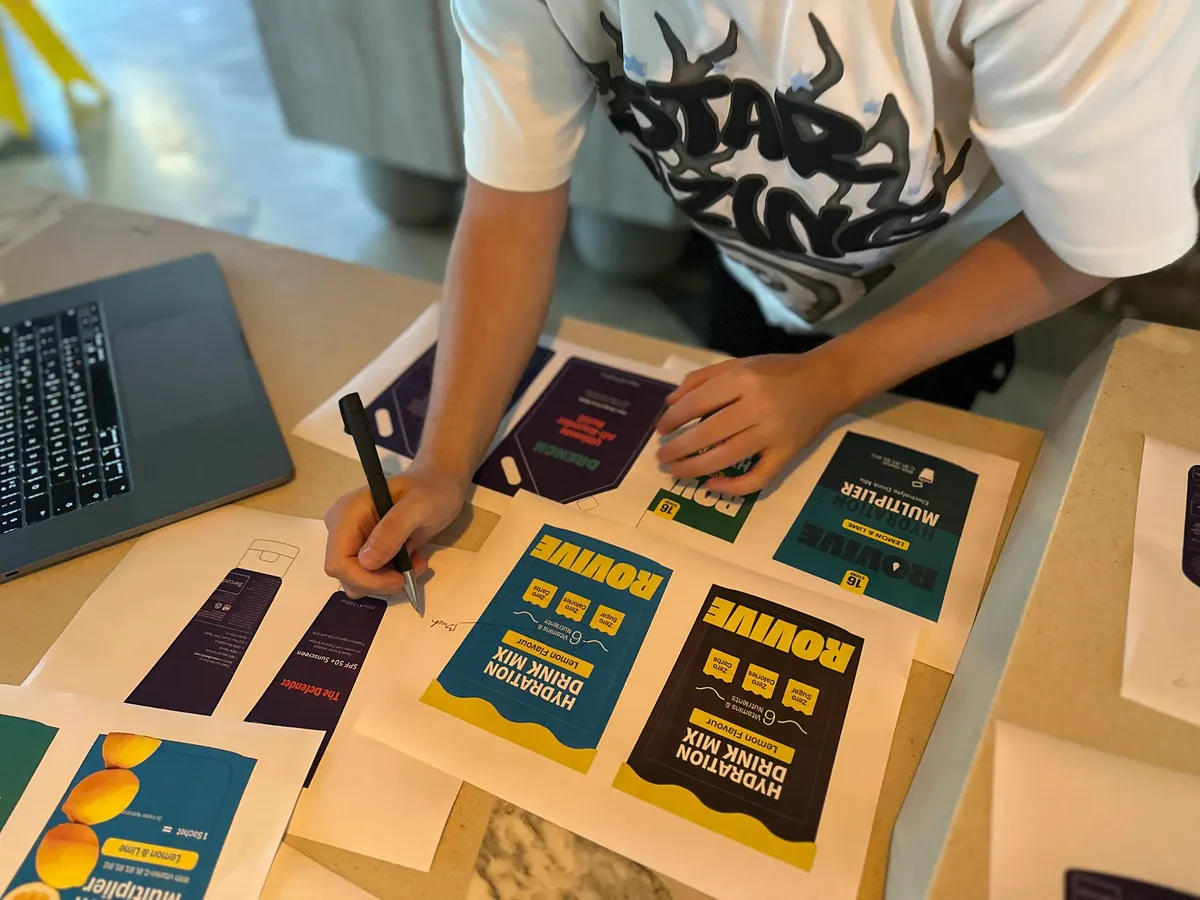

Gone are the days when prototyping was just scissors, glue, and cardboard (though those still make guest appearances). Today, the landscape ranges from hand-crafted mockups to hyper-realistic 3D renderings.

Choosing the right fidelity – low (sketchy but fast), medium (functional but flexible), or high (close to final) – is key. And selecting the right tools depends on your stage in the design process and your testing needs.

Prototyping isn’t just a one-and-done process. It’s iterative – meaning you build, test, get feedback, revise, and repeat. This cycle sharpens your packaging design at every stage, keeping your end result aligned with both user needs and business goals.

It’s a loop:

Design → Prototype → Test → Revise → Repeat

This loop isn’t just about finding flaws – it’s about uncovering opportunities. Whether that’s a new material, an easier opening mechanism, or a more eco-friendly message, iteration gives your packaging room to evolve.

Add in a bit of A/B testing, user feedback loops, and maybe even a sprinkle of environmental testing, and suddenly your packaging is performing like a champ.

BrewDog, the bold Scottish brewery, turns prototyping into a public event. Each year, they launch their Prototype Challenge, releasing a set of limited-edition beers with distinct labels and asking fans to vote for their favourite.

It’s not just a flavour test – it’s a full packaging prototype trial. Each beer comes with custom label artwork, giving the design team the chance to test visual appeal, tone of voice, and shelf impact in real retail settings.

The winning prototype evolves into a permanent product, often with a refined label based on real-world feedback. It’s a perfect example of how packaging prototyping, when paired with live testing, can guide design decisions that actually drive sales.

Dr. Organic, a UK-based natural skincare brand, revamped its packaging to better connect with modern consumers and stand out in retail environments. During the redesign, the team developed several early prototypes to test visual clarity and product differentiation on crowded shelves.

Consumer testing helped refine the design, leading to a clearer hierarchy, stronger brand recognition, and a more cohesive range look. By validating concepts at the prototype stage, Dr. Organic improved both user appeal and in-store performance contributing to a notable boost in sales and brand engagement.

And yes, CAD software, 3D printing, user testing, and design validation all play starring roles here, making sure the packaging design lives up to the hype before it’s mass-produced.

Modern prototyping best practices boil down to a few golden rules: work fast, collaborate early, and test like mad. Speedy iterations, integrated design-feedback loops, and cross-functional collaboration make the difference between a packaging flop and something that flies off the shelf.

Looking forward? Packaging design trends like AR prototyping, AI-driven material selection, and smart packaging with embedded sensors are shaking things up. Not to mention digital twins – digital versions of your physical package that you can test before ever printing a thing.

Prototyping is the backbone of effective packaging design. It enables design teams to test, iterate, and launch confidently. With the right tools and an iterative approach, businesses can transform concepts into packaging that delights users and stands up to real-world challenges.

Let’s work together. We can bring your packaging to life – beautiful, functional, and ready for the real world.